32CrMoV12-10 Steel is a high-quality Cold work tool steel, It belongs to the high-quality high carbon alloy tool steel. It comes under “ Special Steel” Category

» Germany:1.7765

» France: AFNOR 32CDV12

» Europe: 32CrMoV12-10

CHEMICAL COMPOSITION

| C | Cr | SI | Mn | Mo | V | P | S | |

| Min | 0.28 | 2.60 | 0.15 | 0.60 | 0.80 | 0.20 | -- | -- |

| Typical | 0.31 | 2.90 | 0.27 | 0.75 | 1.00 | 0.30 | -- | -- |

| Max | 0.34 | 3.20 | 0.40 | 0.90 | 1.20 | 0.40 | 0.035 | 0.035 |

APPLICATIONS

- » Bolts

- » Screws

- » Crankshafts

- » Automobile Industry

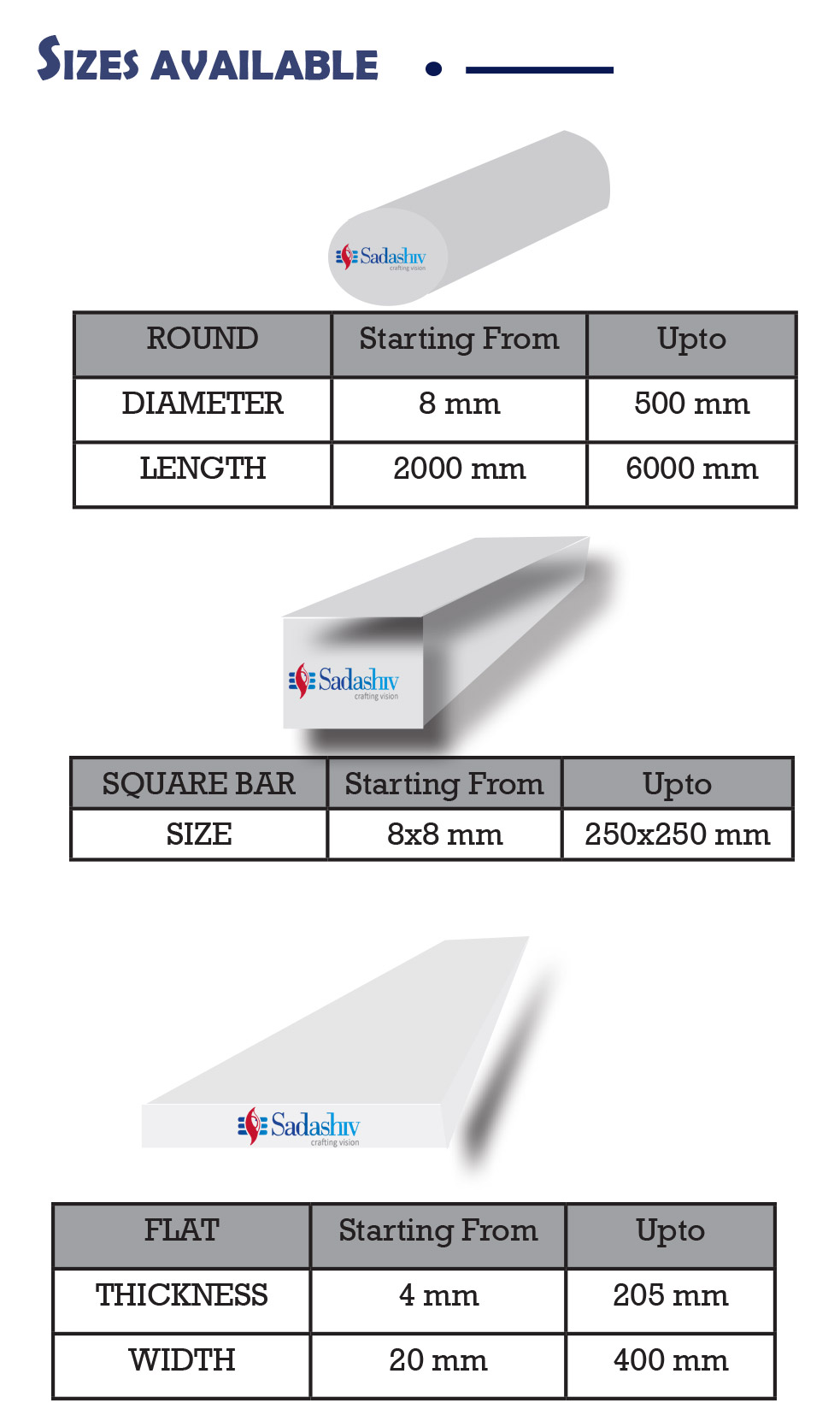

FORM SUPPLIED

- » Round bar

- » Hexagonal bar

- » Square Block

- » Flat Bars

- » Plates

- » Squares

- » Drill Rod

- » Drawn Rounds

Available surface conditions : hot rolled, ground, peeled, turned, drawn, cold rolled

DELIVERY HARDNESS

- » Typical soft annealed hardness is 224 HB

HEAT TREATMENT

- Forged: Slowly heated the 32CrMoV12-10 steel material to 1100-850°C. Initial hammer blows should be light due to the comparatively high hot strength of this steel.

- Annealing: Heat to approx. 720°C, cool slowly. This will produce a maximum Brinell hardness of 224.

- Hardening: DIN 32CrMoV12-10 sheets of steel should be heated uniformly to 850-890°Cuntil completely heated through.

Then withdraw 32CrMoV12-10 steel tools from the furnace, either air cool or oil quench.

| Tool | Hardening | Tempering |

| single edge cutting tools | 1220 ºC | 560 ºC |

| multi edge cutting tools | 1180-1220 ºC | 560 ºC |

| cold work tools | 1050-1150 ºC | 560 ºC |

PROCESSING

32CrMoV12-10 tool steel round bar and flat sections can be cut to your required sizes. 32CrMoV12-10 tool steel ground bar can also be supplied, providing a high-quality tool steel precision ground tool steel bar to your required tolerances. 32CrMoV12-10 steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

GRINDING

During Grinding, local heating of the surface, which can alter the temper, must be avoided. Grinding wheel manufacturers can provide advise on the choice of grinding wheels.

SURFACE TREATMENT

Some Surface treatments for DIN 1.7765 include :

Laser remelting, Nitriding, painting, powder coating, anodizing, plating, grinding, polishing, and abrasion.