H13 Tool Steel is chromium hot work tool steels which are widely used in hot and cold work tooling applications. Due to H13 tool steel excellent combination of high toughness and fatigue resistance, AISI H13 hot work

tool steel is used more than any other tool steel in tooling applications

» USA: AISI H13

» Germany: 1.2344

» Japan: JIS SKD61

» France: AFNORZ40CDV5

| C | Cr | SI | Mn | Mo | V | P | S | |

| Min | 0.32 | 4.75 | 0.80 | 0.20 | 1.25 | 0.80 | -- | -- |

| Typical | 0.40 | 5.10 | 1.00 | 0.40 | 1.50 | 1.00 | -- | -- |

| Max | 0.45 | 5.50 | 1.25 | 0.60 | 1.75 | 1.20 | 0.035 | 0.035 |

APPLICATIONS

- » Dies

- » Backers

- » Dummy blocks

- » Die-holders

- » Wear resisting parts

- » Shrink rings

- » Hot shearing

- » Cold punching scrap

shears

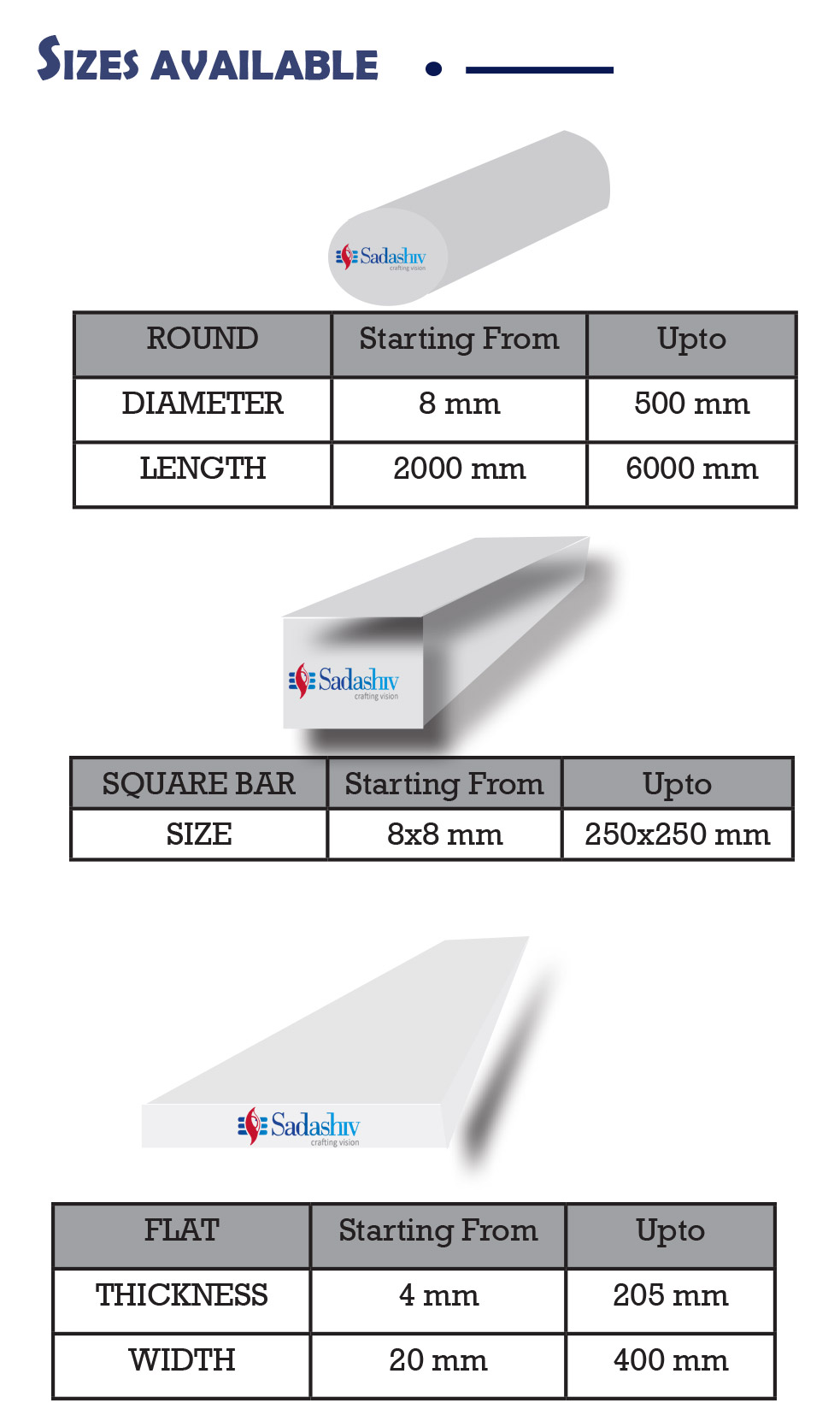

FORM SUPPLIED

- » Rolled Round bar

- » Flat Bar

- » Forged Round bar

Available surface conditions : hot rolled, ground, peeled, turned, drawn, cold rolled

HEAT TREATMENT

- Stress-releiving : When desirable to relieve the strains of machining, heat slowly to 1050°-1250°F, allow to equalize, and then cool in still air.

- Annealing : Heat slowly to 1550°-1650°F, hold until entire mass is heated through, and cool slowly in the furnace (40F per hour) to about 1000°F, after which cooling rate may be increased. Suitable precautions must be taken to prevent excessive carburization or decarburization.

- PreHeat: Warm slightly before charging into the preheat furnace, which should be operating at 1400°-1500°F.

- Hardening: H13 tool steel is a steel having very high hardenability and should be hardened by cooling in still air. The use of a salt bath or controlled atmosphere furnace is desirable to minimize decarburization, and if not available, pack hardening in spent pitch coke is suggested. The temperature employed is usually 1800°-1850°F, depending on size section.

- Quenching : Quench in still air or dry air blast. If complicated forms are to be hardened, an interrupted oil quench can be used. Quench part in oil

and remove from bath when it just loses its color(1000°-1100°F). Finish cooling to below 150°-125°F in air, then temper immediately. - Tempering: practice may vary with size and application, but is usually performed in the range of maximum secondary hardness or higher. Double

tempering is recommended. The results below is H13 that was air quenched from 1800°F and tempered for 4 hours at various temperatures. - Forging: of H13 Tool Steel Heating for forging must be done slowly and uniformly. Soak through at 1900°-2000°F and reheat as often as necessary,

stopping work when the temperature drops below 1650°F. After forging, cool slowly in lime, mica, dry ashes or furnace. H-13 should always be annealed after forging.

| Tool | Hardening | Tempering |

| single edge cutting tools | 1220 ºC | 550-570 ºC |

| multi edge cutting tools | 1180-1220 ºC | 550-570 ºC |

| cold work tools | 1050-1150 ºC | 550-570 ºC |

PROCESSING

H13 can be worked as follows :

- Machining( grinding,turning,milling)

- Polishing

- Hot forming

- Electrical discharge machining

- Welding(special procedure incl. pre-heating & filler

materials of base material composition)

GRINDING

During Grinding, local heating of the surface, which can alter the temper, must be avoided. Grinding wheel manufacturers can provide advise on the choice of grinding wheels

SURFACE TREATMENT

The Steel Grade is a perfect substrate material for PVD coating. If nitriding is requested, a small diffusion zone is recommended but avoid compound and oxidized layers.

DELIVERY HARDNESS

- » Typical soft annealed hardness is 250 HB

- » Cold drawn and cold rolled material is typically 10-40 HB harder