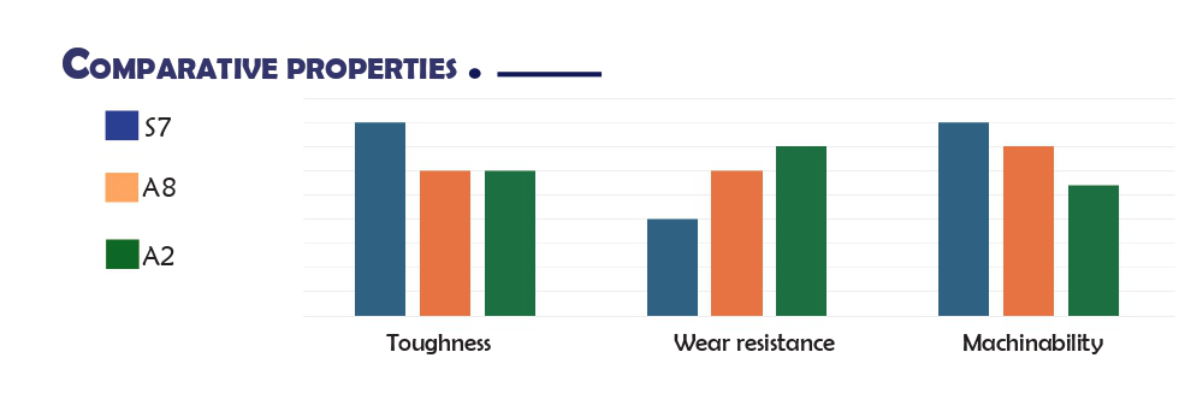

AISI A8 Tool Steel is a versatile, air-hardening tool and die steel that combines good wearing qualities with excellent toughness characteristics. It provides an intermediate level of wear resistance. It belong to the high quality medium carbon high Cr, Mo, V alloy tool steel.

» USA: AISI A8

» FED QQ-T-570

» UNS T30108

| C | Cr | SI | Mn | Mo | W | P | S | |

| Min | 0.50 | 4.75 | 0.75 | 0.20 | 1.15 | 1.00 | -- | -- |

| Typical | 0.55 | 5.10 | 0.90 | 0.35 | 1.40 | 1.25 | -- | -- |

| Max | 0.60 | 5.50 | 1.10 | 0.50 | 1.65 | 1.50 | 0.035 | 0.035 |

APPLICATIONS

- » Slitters

- » Die Shapes

- » Punches

- » Hot rolls

- » Drift pins

- » Pneumatic Tools

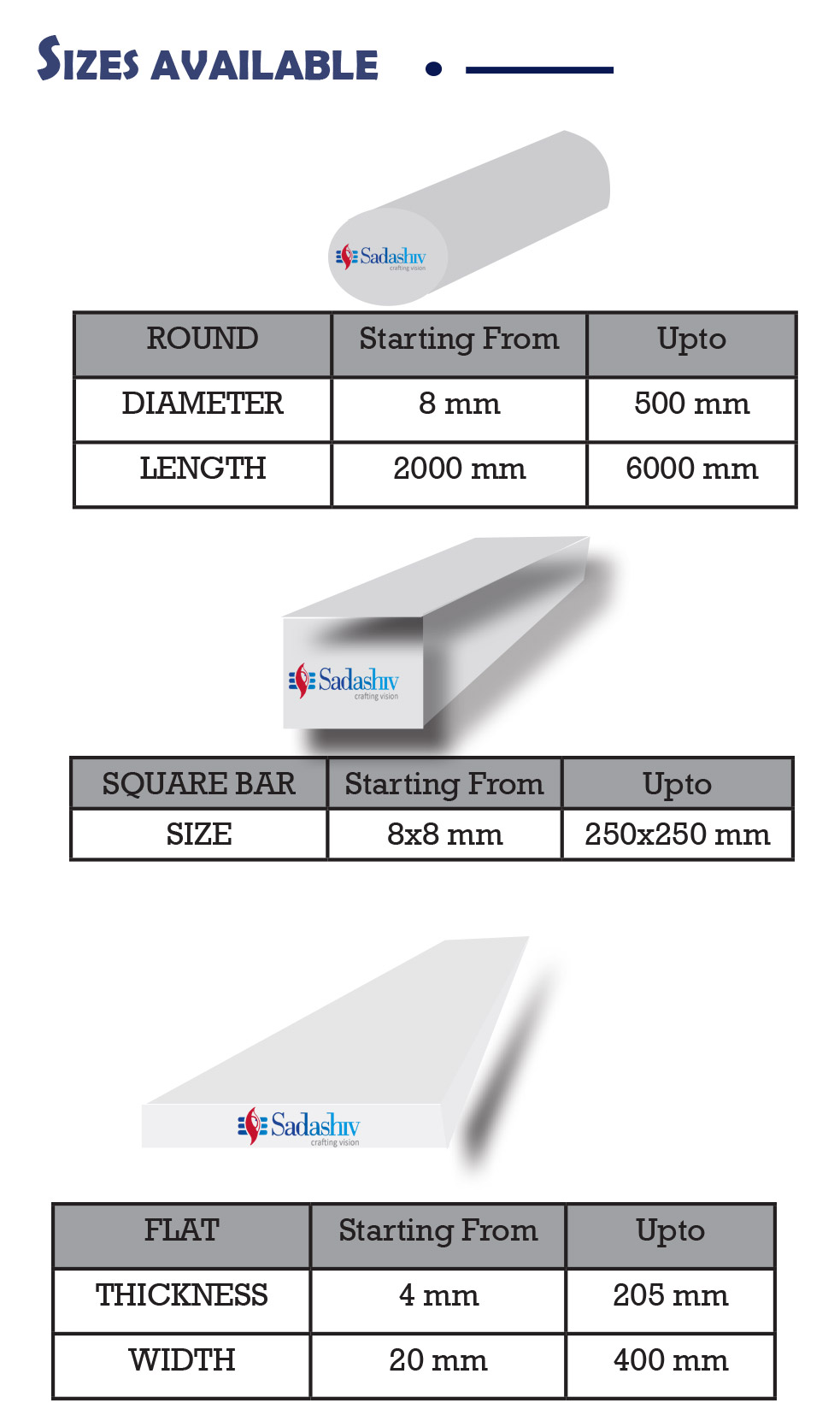

FORM SUPPLIED

- » Round bar

- » Flat Bar

- » Hexagonal bar

- » Plates

- » Square Block

Available surface conditions : hot rolled, ground, peeled, turned, drawn, cold rolled

HEAT TREATMENT

- Forging : Slowly heated the A8 steel material to 650- 680°C (1202-1256°F) before raising the temperature to 1050-1100°C(1922-2120°F) and soak A8 material until uniformly heated. Initial hammer blows should be light due to the comparatively high hot strength of this steel. The A8 steel forged temperature should be maintained above 1000°C(1832°F) until the A8 metal begins to yield. Final forged should not be done below 900°C(1652°F). Slowly cool after forged is essential to avoid the possibility of cracking.

- Annealing : Pre-heated to 788°C(1450°F)The Slowly heated A8 steel to 830-845°C (1526-1553°F) and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace at a rate of 4°C (40°F) per hour or less.

- Hardening : Put the A8 steel in Air, pressurized gas, or interrupted oil to 65-52°C(150-125°F). Soak thoroughly at the temperature for thirty minutes per 25mm of ruling section, then cool or quench accordingly. Sizes over 5 inches in cross section may not achieve full hardness by cooling in still air.

It is usually necessary to increase the quench cooling rate between 760 482°C(1400 to 900°F)by using an air blast, pressurized gas, or an interrupted

oil quench. For the oil quench, quench until black, about 900°F, then cool in still air to 66-52°C(150-125°F).Then withdraw A8 steel tools from the furnace either air cool or oil quench. - Tempering : Tempering of A8 steels is performed at 148-315°C (300-600°F), Double tempering is recommended for tempering temperatures

of 900°F and higher. Soak well at the selected temperature and soak for at least one hour per 25mm of total thickness.

| Tool | Hardening | Tempering |

| single edge cutting tools | 1220 ºC | 550-570ºC |

| multi edge cutting tools | 1180-1220 ºC | 550-570ºC |

| cold work tools | 1050-1150 ºC | 550-570ºC |

PROCESSING

A8 can be worked as follows :

- Machining( grinding,turning,milling)

- Polishing

- Hot forming

- Electrical discharge machining

- Welding(special procedure incl. pre-heating & filler

materials of base material composition)

GRINDING

During Grinding, local heating of the surface, which can alter the temper, must be avoided. Grinding wheel manufacturers can provide advise on the choice of grinding wheels

SURFACE TREATMENT

The Steel Grade is a perfect substrate material for PVD coating. If nitriding is requested, a small diffusion zone is recommended but avoid compound and oxidized layers.

DELIVERY HARDNESS

- » Typical soft annealed hardness is 250 HB

- » Cold drawn and cold rolled material is typically 10-40 HB harder