Steel Ingots and Steel Billets

What’s the Difference?

Forgers use steel billets or ingots to produce a variety of steel products, including components or steel bars in round/ square/flats shapes. However, billets and ingots possess different properties. Here is a closer look at the differences.

Steel Ingots vs. Billets – Production Method

Steel ingots are a block of steel made by pouring hot metal into mould through batch casting. Foundries typically cast ingots using a bottom pouring method. The cross-section of the ingot is either square, rectangular, round or polygonal. The size of the cross-section is tapered from one end of the ingot to the other. It includes the hot top which defines the top of the ingot. The hot-top traps impurities during the casting process as the steel cools and is discarded after the end of production.

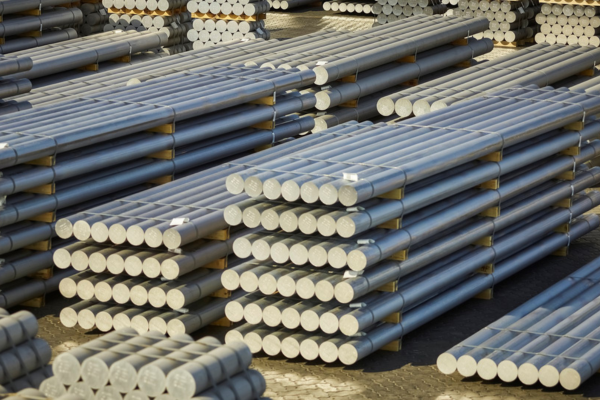

Steel billets were made through continuous casting on a CCM (continuous castings machine). There are usually square but can also be round or flat. The cross section is the same throughout the length of the billet and the lengths can be as per requirement hot cut while casting.

Steel Ingots vs Billets – Durability and Cost

Steel billets are often cheaper compared to steel ingots however, steel ingots offer some advantages when producing round bars and other steel products. The grain flow of steel bars rolled from ingots can be achieved in a lesser reduction ratio compared to CCM-produced steel billets which would require higher reduction ratios.

The capital costs are very low for making larger sized steel ingots than steel billets. Steel ingots can be produced in a variety of customized sizes and shapes as per requirement. Therefore , in case of manufacturing large forgings, steel ingots are used but in case of smaller sizes billets are preferred.

In the end, both steel ingots and steel billets are the preferred choice for respective applications and have their own advantages. Majorly due to cost implications billets are used. With advancement in technology today with EMS (Electromagnetic Stirrer) and AMLC (Auto Mould level controller) , billet quality has come almost at par with ingots for internal soundness in smaller sizes.

SADASHIV CASTINGS PVT.LTD., with our new CCM with EMS and AMLC, our customers can today opt to buy both steel billets or ingots and steel bars made through either of the processes. In our continuous endeavor to reduce the cost for our customers without compromising on quality, our new steel billet manufacturing is now fully operational for 100×100 to 200×200 for all types of alloy steels, low or high.