Cold Works D2 tool steel is a high carbon, high chromium tool steel (12% chrome) with extremely high wear resisting properties, heat treatable to 60-62 Rc. D2 steel is very wear resistant but not as tough as lower alloyed steels.

» USA: AISI D2

» Europe: X153CrMoV12

» Japan: JIS SKD11

» Germany: 1.2379

CHEMICAL COMPOSITION

| C | Cr | SI | Mn | Mo | V | P | S | |

| Min | 1.40 | 11.00 | 0.10 | 0.10 | 0.70 | 0.70 | -- | -- |

| Typical | 1.50 | 12.00 | 0.35 | 0.35 | 0.95 | 0.90 | -- | -- |

| Max | 1.60 | 13.00 | 0.60 | 0.60 | 1.20 | 1.10 | 0.035 | 0.035 |

APPLICATIONS

- » Blanking Dies

- » Forming Dies

- » Slitting Cutters

- » Beading Rolls

- » Gauges

- » Wear Parts

- » Burnishing Tool

- » Sheer Blades

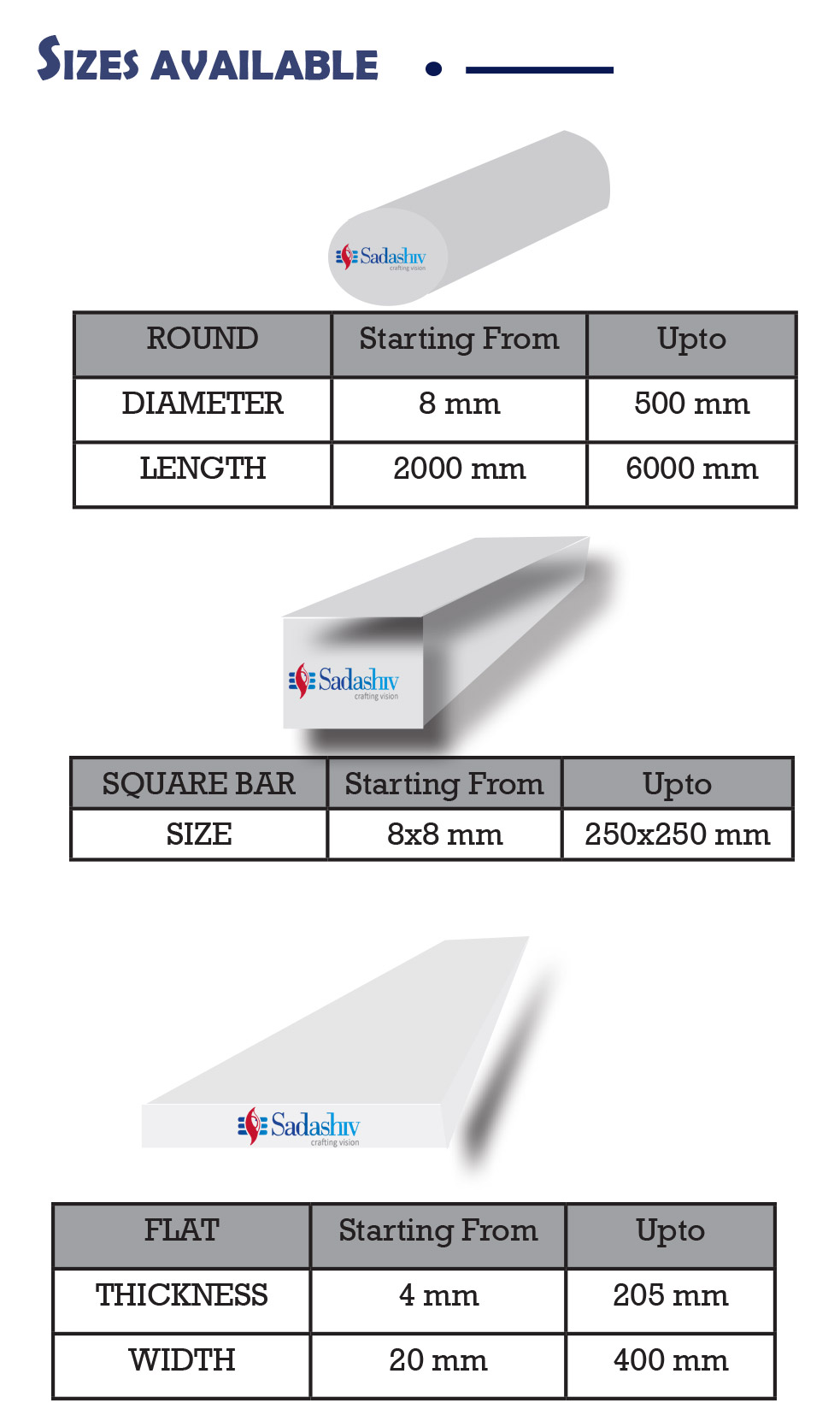

FORM SUPPLIED

- » Round bar

- » Flat Bar

- » Plates

- » Blocks

- » Hot rolled Rounds

- » Squares

- » Drill Rod

- » Drawn Rounds

Available surface conditions : hot rolled, ground, peeled, turned, drawn, cold rolled

HEAT TREATMENT

- Stress-releiving: When desirable to relieve the strains of machining, heat D2 grade steel slowly to 1050°-1250°F, allow to equalize, and then cool in still

air (Strain Relieving). - Annealing: of D2 tool steels material should be done at 871 to 898°C (1600 to 1650°F) followed by slow furnace cooling at 4.4°C (40°F) per hour or less. after which cooling rate may be increased. Suitable precautions must be taken to prevent excessive carburization or decarburization.

- Preheat: slowly to 1350°-1450°F and hold at this temperature until grade steel D2 material is uniformly heated.

- Hardening: After thorough preheating, heat to 1800°-1850°F. Hold the work piece at the hardening temperature until it is completely and uniformly

heated. holding time, each time - Quenching: AISI D2 steel tool material is an air hardening steel and will develop hardness on cooling in still air. To avoid scaling and prevent decarburization of the work piece surface, controlled atmosphere or vacuum furnaces are recommended

- Tempering: The tempering temperature on material D2 steel may be varied according to the desired hardness. D2 steels can be tempered at

204°C (400°F) for achieving Rockwell C hardness of 61 and at 537°C (1000°F) for a Rockwell C hardness of 54.

| Tool | Hardening | Tempering |

| single edge cutting tools | 1220 ºC | 550-570 ºC |

| multi edge cutting tools | 1180-1220 ºC | 550-570 ºC |

| cold work tools | 1050-1150 ºC | 550-570 ºC |

PROCESSING

D2 can be worked as follows :

- Machining( grinding, turning, milling)

- Polishing

- Hot forming

- Electrical discharge machining

- Welding(special procedure incl. pre-heating & filler

materials of base material composition)

GRINDING

During Grinding, local heating of the surface, which can alter the temper, must be avoided. Grinding wheel manufacturers can provide advise on the choice of grinding wheels

SURFACE TREATMENT

The Steel Grade is a perfect substrate material for PVD coating. If nitriding is requested, a small diffusion zone is recommended but avoid compound and oxidized layers.

DELIVERY HARDNESS

- » Typical soft annealed hardness is 220 HB

- » Cold drawn and cold rolled material is typically 10-40 HB harder